India is a very price sensitive market where

customers are ready to shell out an extra penny only if it provides more

reliability or durability. Diesel engines require an extra investment but may

reduce cost of ownership for the owner, thus explaining their huge

popularity.br />

Customers’ opinion on diesel engines generally

comes under two broad categories. Some render them to be noisy, messy and

suffocating and have no liking to them. Others opt for them for their fuel

efficiency, high mileage and more value for money, making the diesel engine a

large market.

Invented by Rudolph Diesel, the world knows the

diesel engine as a powerful powertrain with outstanding pulling power, fuel

efficiency and longevity.

Diesel engines are used in automobiles,

generators, boats and have varied applications with agricultural applications.

Turbo-charged diesel engines are also used in two-wheelers like motorcycles.

The Working of the Diesel

engine

Diesel engines and petrol engines share several

similarities. They have number of components in common such as the crankshaft,

pistons, valves, camshaft, and coolant and and oil pumps. However, a key

difference between the two is that the diesel engine lacks an ignition system.

Instead of relying on a spark for ignition (as in petrol engines), a diesel

engine uses heat produced by compressing air in the combustion chamber to ignite

the fuel. All other systems used in the diesel powered vehicles are essentially

the same as those used in gasoline vehicles, and we refer to the article

published last week on petrol

engines.

Ignition system in diesel

engine

In a diesel engine, fuel injection is used. Fuel

is supplied to a Fuel injection pump and from there to injectors positioned on

each cylinder. Timing and pressure is set to inject a fine spray of diesel at

the end of the compression stroke. The heat of compressed air entered into the

cylinder then ignites the fuel and thus begins the power stroke.

Fundamentally, using compressed, hot air as well

as diesel spray ensures that the air and diesel particles can mix better so that

ignition can take place.

Glow plugs are used in diesel engines only to

warm the combustion chamber when engine is cold. As the above explained, the air

in the cylinder needs to be hot to ignite the diesel spray. Hence, cold starting

is impossible without these plugs because even the high compression ratios

cannot heat cold air enough to cause combustion. Thus when you’re just starting

your engine, these glow plugs will warm up the air in the combustion

chambers.

Schematic comparison of Diesel and

Petrol technology

|

Gasoline |

Diesel |

| Intake |

Air/Fuel |

Air |

| Combustion |

Spark ignition |

Compression ignition |

| Air/Fuel Mixing point |

In intake manifold near intake valve |

In cylinder near Top dead center by Injection |

| Compression ratio |

8 -10 to 1 |

13-25 to 1 |

| Pressure |

464 Psi |

1200 Psi |

| Exhaust |

704- 982 degree centigrade, CO =1% |

371-482 degree centigrade CO=0.5% |

| Efficiency |

22-28 % |

32-38% |

Let’s take a look at the differences and clarify

on why they exist.

First of all, as explained before, in diesel

engines, there is a separate injection for diesel fuel into a diesel engine’s

cylinder, as opposed to the common intake valve in petrol engines, where fuel

and air are injected in one go into the intake valve.

This also means that in petrol engines,

explosion takes place near the fuel intake valve itself, whereas for diesel

engines this takes place properly in the chamber. For the curious ones, it is

this property which makes the two stroke engine still allowable for large power

diesel engines (such as in trains or ships) as the combustion is much more

complete even in a two stroke engine (less leakage), thus combining the power of

the two stroke engine with a high efficiency.

The compression in diesel engines needs to be

much higher to ensure a proper combustion, compared to the more easily ignitable

petrol fuel. As you see, the compression is almost double.

As a result the pressure (1200 Psi vs 464 Psi)

is also more than double!

The temperature of the diesel’s exhaust fumes is

less than petrol engines, due to the technology used, and also, the amount of

noxious gases is also less in petrol gases.

Finally, all this culminates in a higher fuel

efficiency for diesel engines.

Types of Diesel Engines

Diesel engines come in both two stroke or four

stroke engines, differing from petrol engines only in their ignition systems.

Large diesel vehicles usually use 2-stroke configuration for simplicity though

passenger vehicles tend to have 4-stroke configuration. Over the years,

variations have been developed for diesel engines. Let’s take a look at some

engine types.

CRDi Engine

Common Rail Direct Engines are favourites

amongst Mahindra automobiles in India. Globally, they are widely used by Fiat

automobiles which are known to be extremely robust cars. In India, apart from

Mahindra, Hyundai Accent, Ford Motors and BMW automobiles widely use CRDi

engines. They are variation of direct injection engines but are less noisy, less

messy and cleaner.

More specifically, in CRDi engines, there is a

‘common rail’ containing the diesel to be injected into the cylinders. This

common rail serves as an accumulator for fuel and pressure to spray the diesel

is built up in this common rail, instead of in the individual injectors thus

allowing better control of the pressure and uniform pressure while injecting.

Importantly, as the pressure in the diesel (needed for spraying) is built up in

a different component, the pressure can be maintained consistently, so that the

engine is more efficient and smoother.

TDI Engine – Turbo-charged Direct

Injection

The TDI engine is a technology developed by the

Volkswagen group. In these engines, a turbocharger is added to the multi-jet

fuel injection engine which helps in increasing the performance of the engine.

This turbo charger further compresses the air which is provided to the cylinder,

while keeping it cooled as well, thus increasing the amount of air which is

available to ignite the diesel spark.

The result of the larger amount of air is that

more fuel can be injected for combustion, while this combustion is also more

complete. It thus reduces emissions drastically making diesel engines cleaner,

while the power of the car is also increased.

Initially seen in VW Group cars, turbodiesels

are now also used by BMW, among others.

Multi-jet Fuel injection Engine

Multi jet diesel engines are what Fiat Group

companies call their common rail diesel engines. These are the engines that in

India power Maruti cars, such as the Maruti Swift Dzire, Suzuki Swift Diesel,

Tata Cars, such as the Indica, and of course Fiat Group cars, including the

Palio.

These engines were developed by Fiat Group and

feature Common Rail technology, but also Turbo technology, compressing the air

further before combustion.

Naturally Aspirated

They are direct injection engines without a

turbocharger. Then engine draws the air through air filter which passes through

a monitoring meter into the combustion chamber. They produce less power and also

have low pulling power. They are generally used to make automobiles cheaper as

turbocharged engines are more expensive than naturally aspirated ones.

Benefits of Diesel Engines

- Fuel Efficiency

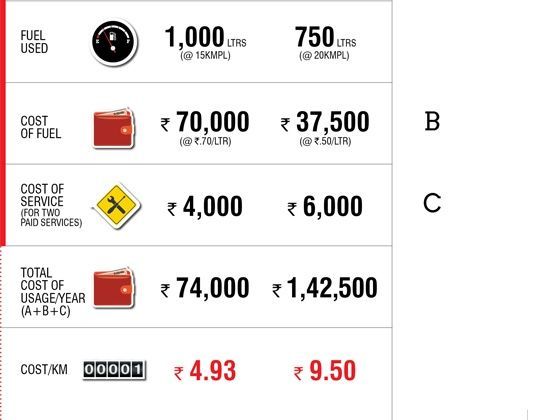

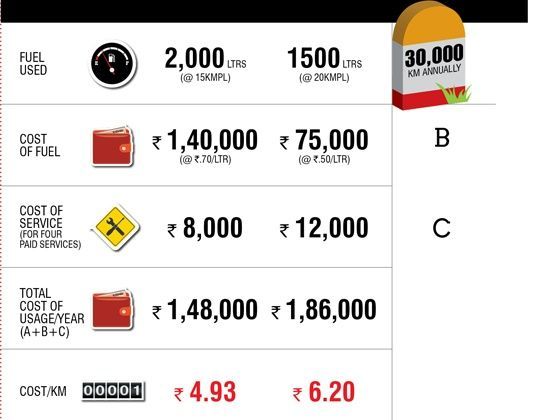

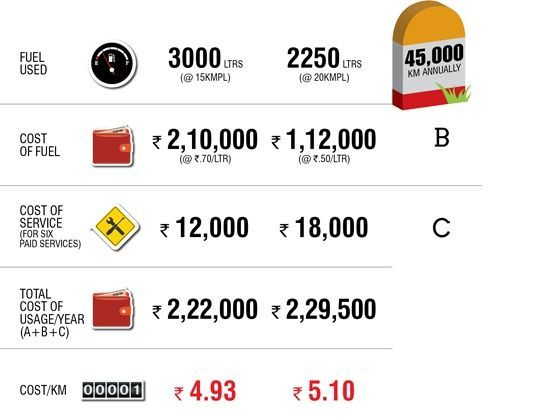

In a weight to weight comparison, diesel per volume

unit contains more energy than petrol, i.e. it has a higher calorific value.

Thus, if a complete ignition of diesel takes place, the engine will deliver more

power than a petrol engine. Equivalently, a smaller amount of diesel is needed

to deliver a certain amount of power. As a result, the diesel car’s mileage is

better than the petrol car’s.

At the same time, with diesel fuel cheaper

than petrol fuel (since diesel is unrefined and thus requires less work from the

oil company), the running cost of a diesel engine becomes lower than a petrol

engine’s.

Hence, if you have been thinking of a hybrid car but limited by

its price, then think of diesel engines. Although diesel engines cannot deliver

the eco-friendliness of hybrid models they can definitely match the fuel

efficiency.

- Safety

Diesel engines are safer than gasoline engines. They are less

volatile than the petrol engine which means they are less likely to explode in

case of a car crash

- Longevity

Diesel engines last longer as they are less prone to wear

and tear. This makes diesel automobiles more cost effective. Moreover, vehicles

used for long runs opt for diesel engines. Diesel engines require less

maintenance and are robust in nature.

However, maintenance when

undertaken for a diesel engine, will be more expensive than for a petrol engine,

as it is a more complex technology. Similarly, the initial investment for a

diesel vehicle is also more, for the same reason.

Thus, the buyer should

ideally offset the investment and maintenance expectation against the savings to

be expected from the better mileage.

- Torque or Pulling Power

Diesel engines have greater pulling power

which clubbed with their tendency to last longer converts commercial and

passenger vehicles to more value for money. However, acceleration is less for

diesel engines.

- Environment

It may be surprising to you, but diesel engines are

considered as cleaner than petrol engines. This is due to a more complete

combustion. Hence, though the emission in diesel engines is more visible

(dusty), petrol engines emit invisible noxious gases.

An interesting

recent development is bio-diesel, which is a animal or vegetable fat based fuel

which has properties equivalent to diesel.

Do read this more thorough analysis

and comparison of petrol and diesel engines for more information. as well as

this comparison

of petrol, diesel and LPG.

Conclusions

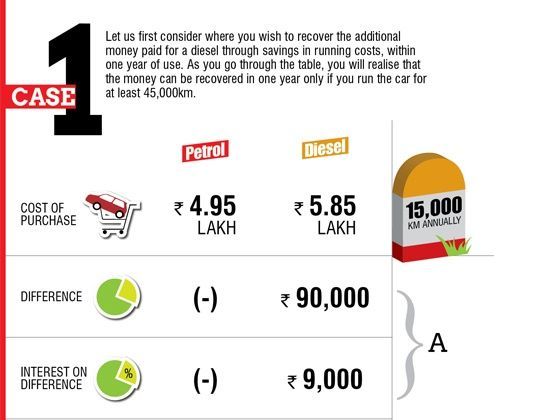

With the steep increase in price of petrol every

fortnight, there is an increased tendency to go for diesel engine cars as the

trade off between the investment of the diesel engine and its lower running cost

is tipping. This has resulted in almost all manufacturers coming up with both

petrol and diesel version their car models. The present generation diesel

engines have started to overcome earlier defects such as cold starting problem

(waiting for the glow plug to heat the air before starting the engine) as well

as improved noise reduction technology to overcome excessive noise from diesel

engines.

The improvements have resulted in smoother

operation of the diesel engines, though the difference to the petrol engines

version remains around rs 75,000. Hence customers may remain in dilemma whether

to invest high for diesel engine version or to go for petrol version.

Our earlier articles on selection between petrol

and diesel engines and alternative fuels will certainly help in this regard.

We hope the above has shed some light on the

working of the diesel engine and its advantages. We remind you that much

technology between diesel and petrol is similar, and thus you should read both

articles in conjuction.

Maintenance of your diesel

car

Maintenance plays a major role in controlling

smoke. Good maintenance is a must to get low smoke levels - or vice versa, low

smoke levels show good maintenance. Improper maintenance affects the injection

characteristics and quantity of lubricating oil which pass across piston rings

and thus exercise a significant effect on engine tendency to generate smoke.

Following the scheduled maintenance as mentioned

in particular car owner manual is needed to ensure good condition.

Diesel odour and its control

The general complaint with diesel vehicles is

about their foul smell or odour. It is due to products of oxidation of fuel in

exhaust. The partial oxidation may be because of very lean mixtures of fuel and

air such as during idling or due to quenching effect. Factors such as Fuel/air

ratio, Engine operation mode, engine type, fuel consumption affect odour

production.

Though many manufacturers claim that odour

additive compounds can reduce intensity of odour, it has been found in practice

that these hardly have any effect.

Source:cartrade.com